GOST 17376 Butt Weld Tees: Seamless and Welded, Carbon Steel and Low Alloy Steel Alloy Steel Bw

Стальные тройники ГОСТ 17376-2001 применяются для труб различного назначения, в том числе для систем управления, при PN до 160 МПа и температурах от -70 °C до +450 °C.

Обзор:

Диаметр тройника 1, D 21,3-355,6 мм

Диаметр тройника 2, D 45-426 мм

Материал 20, 09G2S

Модель создает общие рекомендации для бесшовных сварных панелей и переходов из углеродистых и металлических сплавов.

Пример условного обозначения стальных тройников по Гост 17376-2001:

– Исполнение равнопроходное калибра 2, D = 426 мм, Т = 10 мм из стали 20 :

Тройник 426х10-20 ГОСТ 17376-01,

– то же из стали 09Г2С для труб, контролируемых регулирующим органом:

Тройник Р 426х10-09Г2С ГОСТ 17376-01,

– Тройник переходной исполнения 1, D = 355,6 мм, Т = 11 мм, D1 = 219,1 мм, Т1 = 8 мм из стали 20:

Тройник 1-355.6х11-219.1х8-20 ГОСТ 17376-01.

GOST 17376 – Seamless welded pipeline parts from carbon and low alloy steel TEES

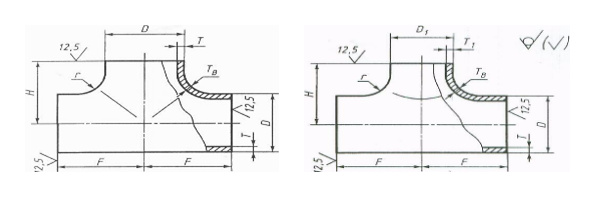

GOST 17376 equal and reducing tee

| DN | D | T | D1 | T1 | F | H | Масса. кг |

| 15 | 2.0 | 21.3 | 2.0 | 25 | 25 | 0.19 | |

| 21.3 | 3.2 | 3.2 | 0.30 | ||||

| 4.0 | 4.0 | 0.38 | |||||

| 20 | 26.9 | 2.0 | 2.0 | 29 | 29 | 0.26 | |

| 3.2 | 3.2 | 0.42 | |||||

| 4.0 | 4.0 | 0.52 | |||||

| 2.0 | 26.9 | 2.0 | 0.23 | ||||

| 3.2 | 3.2 | 0.37 | |||||

| 4.0 | 4.0 | 0.46 | |||||

| 25 | 33.7 | 2.3 | 21.3 | 2.0 | 38 | 38 | 0.25 |

| 3.2 | 3.2 | 0.35 | |||||

| 4.5 | 4.0 | 0.4 | |||||

| 2.3 | 26.9 | 2.0 | 0.25 | ||||

| 3.2 | 3.2 | 0.35 | |||||

| 4.5 | 4.0 | 0.40 | |||||

| 2.3 | 33.7 | 2.3 | 0.40 | ||||

| 3.2 | 3.2 | 0.64 | |||||

| 4.5 | 4.5 | 0.80 | |||||

| 32 | 42.4 | 2.6 | 21.3 | 2.0 | 48 | 48 | 0.79 |

| 3.6 | 3.2 | 1.10 | |||||

| 5.0 | 4.0 | 1.50 | |||||

| 2.6 | 26.9 | 2.0 | 0.79 | ||||

| 3.6 | 3.2 | 1.10 | |||||

| 5.0 | 4.0 | 1.50 | |||||

| 2.6 | 33.7 | 2.3 | 0.79 | ||||

| 3.6 | 3.2 | 1.1 | |||||

| 5.0 | 4.0 | 1.5 | |||||

| 2.6 | 42.4 | 2.6 | 0.79 | ||||

| 3.6 | 3.6 | 1.10 | |||||

| 5.0 | 5..0 | 1.50 | |||||

| 40 | 48.3 | 2.6 | 26.9 | 2.0 | 57 | 57 | 1 .00 |

| 3.6 | 3.2 | 1.40 | |||||

| 5.0 | 4.0 | 2.00 | |||||

| 2.6 | 33.7 | 2.3 | 1.00 | ||||

| 3.6 | 3.2 | 1.40 | |||||

| 5.0 | 4.5 | 2.00 | |||||

| 2.6 | 42.4 | 2.6 | 1.00 | ||||

| 3.6 | 3.6 | 1.40 | |||||

| 5.0 | 5.0 | 2.00 | |||||

| 2.6 | 48.3 | 2.6 | 1.00 | ||||

| 3.6 | 3.6 | 1.4 | |||||

| 5.0 | 5.0 | 2.00 | |||||

| 50 | 60..3 | 2.9 | 33.7 | 2.9 | 64 | 51 | 1.60 |

| 4.0 | 4.0 | 2.20 | |||||

| 5.6 | 5.6 | 3.00 | |||||

| 2.9 | 42.4 | 2.6 | 57 | 1.60 | |||

| 4.0 | 3.6 | 2.20 | |||||

| 5.6 | 5.0 | 3.00 | |||||

| 2.9 | 48.3 | 2.6 | 60 | 1.60 | |||

| 4.0 | 3.6 | 2.20 | |||||

| 5.6 | 5.0 | 3.00 | |||||

| 2.9 | 60.3 | 2.3 | 64 | 1.60 | |||

| 4.0 | 3.2 | 2.20 | |||||

| 5.6 | 4.5 | 3.00 | |||||

| 65 | 76.1 | 2.9 | 2.6 | 64 | 3.20 | ||

| 5.0 | 42.4 | 3.6 | 64 | 5.50 | |||

| 7.1 | 5.0 | 76 | 7.90 | ||||

| 2.9 | 48.3 | 2.9 | 3.20 | ||||

| 5.0 | 4.0 | 5.50 | |||||

| 7.1 | 5.6 | 7.90 | |||||

| 2.9 | 60.3 | 2.6 | 67 | 3.20 | |||

| 5.0 | 3.6 | 5.50 | |||||

| 7.1 | 5.0 | 7.90 | |||||

| 2.9 | 76.1 | 2.9 | 3.20 | ||||

| 5.0 | 5.0 | 5.50 | |||||

| 7.1 | 7.1 | 7.90 | |||||

| 80 | 88.9 | 3.2 | 48.3 | 2.9 | 86 | 73 | 2.9 |

| 5.6 | 4.0 | 4.0 | |||||

| 8.0 | 5.6 | 5.6 | |||||

| 3.2 | 60.3 | 2.9 | 76 | 2.9 | |||

| 5.6 | 4.0 | 4.0 | |||||

| 8.0 | 5.6 | 5.6 | |||||

| 3.2 | 76.1 | 2.9 | 83 | 2.9 | |||

| 5.6 | 5.0 | 5.0 | |||||

| 8.0 | 7.1 | 7.1 | |||||

| 3.2 | 88.9 | 3.2 | 0.86 | 3.2 | |||

| 5.6 | 5.6 | 5.6 | |||||

| 8.0 | 8.0 | 8.0 | |||||

| 100 | 114.3 | 3.6 | 60.3 | 2.7 | 105 | 89 | 3.80 |

| 6.3 | 4.0 | 6.70 | |||||

| 8.8 | 5.6 | 10.00 | |||||

| 3.6 | 76.1 | 2.9 | 95 | 4.50 | |||

| 6.3 | 5.0 | 7.80 | |||||

| 8.8 | 7.1 | 10.0 | |||||

| 3.6 | 88.9 | 3.2 | 98 | 4.50 | |||

| 6.3 | 5.6 | 7.80 | |||||

| 8.8 | 8.0 | 10.00 | |||||

| 3.6 | 114.3 | 3.6 | 105 | 4.50 | |||

| 6.3 | 6.3 | 7.80 | |||||

| 8.8 | 8.8 | 10.00 | |||||

| 125 | 139.7 | 4.0 | 76.1 | 2.9 | 124 | 108 | 3.40 |

| 6.3 | 5.0 | 5.30 | |||||

| 10.0 | 7.1 | 16.00 | |||||

| 4.0 | 88.9 | 3.2 | 111 | 3.40 | |||

| 6.3 | 5.6 | 5.30 | |||||

| 10.0 | 8.0 | 16.00 | |||||

| 4.0 | 114.3 | 3.6 | 117 | 3.40 | |||

| 6.3 | 6.3 | 5.30 | |||||

| 10 | 8.8 | 16.00 | |||||

| 4.0 | 139.7 | 4.0 | 124 | 3.40 | |||

| 6.3 | 6.3 | 5.30 | |||||

| 10.0 | 10.0 | 16.00 | |||||

| 150 | 168.3 | 4.5 | 88.9 | 3.2 | 143 | 124 | 9.40 |

| 7.1 | 5.6 | 16.00 | |||||

| 11.0 | 8.0 | 24.00 | |||||

| 4.5 | 114.3 | 3.6 | 130 | 9.40 | |||

| 7.1 | 6.3 | 16.00 | |||||

| 11.0 | 8.8 | 24.00 | |||||

| 4.5 | 139.7 | 4.0 | 137 | 9.40 | |||

| 7.1 | 6.3 | 16.00 | |||||

| 11.0 | 10.0 | 24.00 | |||||

| 4.5 | 168.3 | 4.5 | 143 | 9.40 | |||

| 7.1 | 7.1 | 16.00 | |||||

| 11.0 | 11.0 | 24.00 | |||||

| 200 | 219. 1 | 6.3 | 114.3 | 3.6 | 178 | 156 | 16.00 |

| 8.0 | 6.3 | 20.00 | |||||

| 12.5 | 8.8 | 43.00 | |||||

| 6.3 | 1 39.7 | 4.0 | 162 | 16.00 | |||

| 8.0 | 6.3 | 20.00 | |||||

| 12.5 | 10.0 | 43.00 | |||||

| 6.3 | 168.3 | 4.5 | 168 | 16.00 | |||

| 8.0 | 7.1 | 20.00 | |||||

| 12.5 | 11.0 | 43.00 | |||||

| 6.3 | 219.1 | 6.3 | 178 | 23.00 | |||

| 8.0 | 8.0 | 29.00 | |||||

| 12.5 | 12.5 | 44.00 | |||||

| 250 | 273.0 | 6.3 10.0 |

139.7 | 4.0 6.3 |

216 | 191 | 33.0 52.0 |

| 6.3 10.0 |

168.3 | 4.5 7.1 |

194 | 33.0 52.0 |

|||

| 6.3 10.0 |

219.1 | 6.3 7.1 |

203 | 33.0 52.0 |

|||

| 6.3 10.0 |

273.0 | 6.3 10.0 |

216 | 33.0 52.0 |

|||

| 300 | 323.9 | 7.1 10.0 |

168.3 | 4.5 7.1 |

254 | 219 | 47.00 66.00 |

| 7.1 10.0 |

219.0 | 6.3 8.0 |

229 | 47.00 66.00 |

|||

| 7.1 10.0 |

273.0 | 6.3 8.0 |

241 | 47.00 66.00 |

|||

| 7.1 10.0 |

323.9 | 7.1 10.0 |

.254 | 54.00 77.00 |

|||

| 350 | 355.6 | 8.0 11 |

219.1 | 6.3 | 279 | 248 | __ |

| 8.0 11 |

273.0 | 6;3 10.0 | 257 | ||||

| 8.0 11 |

323.9 | 7.1 10.0 | 270 | ||||

| 8.0 11 |

355.6 | 8.0 11.0 | 279 | 68.00 94.00 | |||

| 400 | 406.4 | 8.8 12.5 |

273.0 | 6.3 10.0 | 305 | 283 | __ |

| 8.8 12.5 |

323.9 | 7.1 10.0 | 295 | ||||

| 8.8 12.5 |

355.6 | 8.0 10.0 | :305 | __ | |||

| 8.8 12.5 |

406.4 | 8.8 12.5 | 88.00 131.00 | ||||

| 450 | 457.0 | 10.0 | 323.9 | 7.1 | 343 | 321 | — |

| 355.6 | 8.0 | 330 | |||||

| 355.6 | 11.0 | ||||||

| 406.4 | 8.8 | ||||||

| 457.0 | 10.0 | 343 | |||||

| 500 | 508.0 | 11.0 | 355.6 | 8.0 | 381 | 356 | — |

| 406.4 | 8.8 | ||||||

| 457.0 | 10.0 | 0.368 | |||||

| 508.0 | 11.0 | 381 | |||||

| 600 | 610.0 | 12.5 | 406.4 | 8.8 | 432 | 406 | — |

| 457.0 | 10.0 | 419 | |||||

| 508.0 | 11.0 | 432 | |||||

| 610.0 | 12.5 | ||||||

| 700 | 711.0 | —- | 711.0 | __ | 521 | 521 | — |

| 800 | 813.0 | 813.0 | 597 | 597 | |||

| 900 | 914.0 | 914.0 | 673 | 673 | |||

| 1000 | 1016.0 | 1016.0 | 749 | 749 |

Wilson Pipeline is a leading manufacturer and distributor of flange fittings material from alloy steel stainless steel to carbon steel.products, including Super Duplex Stainless Steel Flanges, Stainless Steel Flanges, Stainless Steel Pipe Fittings. ASME B16.5 ASME B16.9 ASME B16.11 EN1092,ANSI ASTM,GOST,JIS,DINWilson Pipeline products are widely used in Shipbuilding, Nuclear power, Marine engineering, Petroleum, Chemical, Mining, Sewage treatment, Natural gas and Pressure vessels and other industries.If you want to have more information you want to share your enquiry with us, contact us at sales@wilsonpipeline.com