what’s the Insulation Pillows fabric expansion joint

Fabric expansion joints are extremely flexible and can be made from a variety of special woven fabrics coated or laminated with selected elastomers or fluoropolymers. Fabric bellows are used to insulate, to avoid mechanical loads and to protect against abrasion.

The main advantage of a fabric expansion joint for pipework design is that it can absorb movements simultaneously in several directions. Further, fabric bellows have almost no reactive forces and require little space. Fabric bellows are easy to customize to suit existing operating conditions and are easy to transport and install.

In comparison to metallic expansion joints; fabric expansion joints offer almost unlimited flexibility by giving pipework designers more options. Mostly, fabric expansion joints are installed in systems operating with low pressure and dry media.

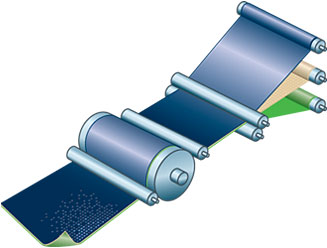

Flexible Element Components

The flexible element is the most active component of the expansion joint. It contains the gas seal and must be 100% non-permeable, and allow movement in all directions. The flexible element’s Structural Gas Ply must also be designed to withstand the system temperature and pressure and be chemically compatible. The Flexible Element may also include additional thermal barriers, as well as retaining and reinforcing plies. MIPR Corp offers flexible elements in both Flat Belt and U-Shaped “Integrally Flanged” varieties, and when combined with additional thermal layers and insulation pillows, are suitable for temperatures up to 2000°F.

The flexible element is the most active component of the expansion joint. It contains the gas seal and must be 100% non-permeable, and allow movement in all directions. The flexible element’s Structural Gas Ply must also be designed to withstand the system temperature and pressure and be chemically compatible. The Flexible Element may also include additional thermal barriers, as well as retaining and reinforcing plies. MIPR Corp offers flexible elements in both Flat Belt and U-Shaped “Integrally Flanged” varieties, and when combined with additional thermal layers and insulation pillows, are suitable for temperatures up to 2000°F.

Wilson Pipeline is a leading manufacturer and distributor of flange fittings material from alloy steel stainless steel to carbon steel.products, including Super Duplex Stainless Steel Flanges, Stainless Steel Flanges, Stainless Steel Pipe Fittings. ASME B16.5 ASME B16.9 ASME B16.11 EN1092,ANSI ASTM,GOST,JIS,DINWilson Pipeline products are widely used in Shipbuilding, Nuclear power, Marine engineering, Petroleum, Chemical, Mining, Sewage treatment, Natural gas and Pressure vessels and other industries.If you want to have more information you want to share your enquiry with us, contact us at sales@wilsonpipeline.com