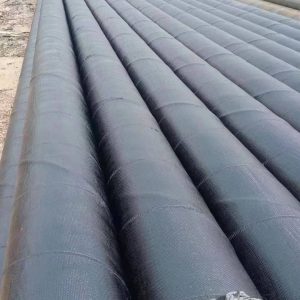

SSAW Steel pipe

ERW is-high-frequency resistance welding-straight seam welded pipe; LSAW is-submerged arc welding-straight seam welded pipe; both belong to straight seam welded pipe, but the two have different welding processes and different uses, so they cannot represent straight seam welded pipe alone. SSAW-spiral welding-spiral welded pipe is more common.

large diameter ssaw spiral steel pipe for water pipe line

Quick Details

- Place of Origin:

-

Tianjin, China

- Application:

-

Fluid Pipe

- Alloy Or Not:

-

Non-Alloy

- Section Shape:

-

Round

- Special Pipe:

-

API Pipe

- Outer Diameter:

-

219 – 2032 mm

- Thickness:

-

5 – 25 mm

- Standard:

-

API, ASTM, GB, JIS, bs, API 5CT, API 5L, ASTM A53-2007, ASTM A53M-2007, ASTM A252-1998, GB/T 9711.1-1997, GB/T 3091-2001, JIS G3466, BS EN10296

- Technique:

-

SAW

- Grade:

-

A53(A,B), A106(B,C), A335 P9, A335 P12, 16mn, ST37, St37-2, ST35, Q235, Q345, Q195, Q215, A53-A369, 16mn, ST35-ST52, Q195-Q345

- Surface Treatment:

-

oiled, black painting, 3lpe coating

- Tolerance:

-

±5%

- Processing Service:

-

Bending, Welding, Decoiling, Punching, Cutting

- Product name:

-

Spiral Welded Steel Pipe

- Length:

-

1-18m

- Secondary Or Not:

-

Non-secondary

- End protector:

-

Bevel Ends

- Service:

-

OEM, Sample Free

- Usage:

-

Construction Structure

- Material:

-

Q195/Q235/Q345

- Key words:

-

Spiral Submerged Welded Steel Pipe

- MOQ:

-

25 Tons

- Payment terms:

-

30%TT Advance + 70% Balance

- Certification:

-

API