EN 1092-1 flange manufacturer,inventory supplier welded flange stainless steel, carbon steel and nickel alloy flanges Material Stander Datasheet

EN 1092-1 flange manufacturer, supplier, stockist – type 01 plate flange (sliding sleeve) stainless steel, carbon steel and nickel alloy 1092-1 flange for welding

·Etallica specializes in producing high-quality en1092-1 flanges of various grades and sizes. Our en1092-1 flange manufacturing range is 1/2 “(DN15) ~ 60” (DN1500), with customized thickness and standard thickness

·The types of en1092-1 flanges include various types of en1092-1 flanges, such as 01 type flat flange (sliding sleeve) for weld ing

Type 02 loose disc flange with welding ring or loose disc flange with welding ring for overlapping pipe end type 04, type 05 blind flange, type 11 welding ring flange, type 12 welding sliding flange with hub, type 13 threaded flange with hub, type 21 integral flange, type 32 welding ring, type 33 overlapping pipe end type 34 welding ring, type 35 welding neck, type 36 pressure ring with long neck, type 37 pressure ring

·We can produce en1092-1 flanges with various surface treatments, such as antirust paint, black paint and yellow paint

Ede1092-1 flanges, which are transparent, galvanized, cold galvanized and hot-dip galvanized, have various surface types, including flat (FF). B-convex (RF), c-tongue groove, e-socket, f-groove, g-o-ring socket, o-groove. In various flange manufacturing specifications, we can produce flanges according to the following requirements:

Carbon steel flange: astma105sa516 gr7s355j2+n

Low temperature flange: ASTM A350 lf1 lf2 cl1/cl2lf3cl1/cl2

Stainless steel flange: ASTM A182 f304/304lf316/316lf321astm a240 TP304, ASTM a240 TP316L Austrian alloy steel flange: ASTM F1 F5 f9f11f91 o high yield strength flange: a694 F42 f52 F60 F65

Ospecial alloys flange: nickel alloy, inconelhastelloy titanium alloy copper nickel iron alloy o dual phase steel flange-22052507 uns s32205 uns s31803 uns s32760. UNS S32750

En1092-1 flange products and scope of supply

Product en1092-1 flange

Size 1/2 (DN15) -60 (DN1500)

A-plane (FF) b-convex (RF) C-convex e-socket f-concave g-o-ring

Flange seat

H-shaped annular groove

Rated pressure 150\35×2500\35hzl (pn6-pn40)

Forging type, plate cutting, casting

Certificate en 10304 3.1

Flange manufacturing standard

Ansi/asme flanges

• ansi/asme B16 series 5ansi/asme b16.47 a (msssp-44) ansi/asme b16.47 B (api605)

ANSI/ASMEB16.36 ANSI/ASME B16.48(API590)

BS flange

• form bs10 de F hi krst bs4504 code 1011051111111 bs1042

Din flange

DIN2527 DIN2573DIN2576DIN2502DIN503 DIN2543 DIN2544 DIN2545 DIN2630DIN2631DIN2632DIN2633 DIN2634

D 2635. Ding 2636. DIN2637.DIN2638DIN2628DIN2629DIN2627DIN2641DIN642DIN6502DIN653DIN2655。 DIN2656 DIN2673DIN2674DIN2675DIN2676DIN2558DIN2561DIN2565DIN2566DIN2567。 DIN2568DIN2569DIN281155DIN86029 DIN86030

EN 1092-1

·Type: white flat flange (sliding lining), for type 02 welded plate ring or lap pipe

Terminate 04 type flange with welding neck, 5 type blind flange, 11 type welding flange, 12 type welding flange with hub, 13 type threaded 21 type integral flange, 32 type welding flange. 33 type lap pipe end 34 type neck welding ring. Tvpe 35 welding neck 36 long neck compression ring 37

China Professional Flange supplier Manufacture Wilson Pipeline.

-What flange type?

Flanges can be represented and classified in different ways, such as

Connection type.

-Rated pressure and temperature – material type

Anchor flange Fixed flange Expansion flange High wheel flange Lap flange Flange with blade and ring gasket Adapter flange Welding flange Square flange Main standard steel flange

The welded neck flange is welded to the end of the pipe for high-pressure applications to reduce stress concentration. It is generally processed by forgings. These flanges are usually welded to the tubular welding neck of the flange, and the flange has a higher life expectancy than the sliding flange under pressure.

Sliding flange is usually lower than welded neck flange, so it is a

Many users have popular choices. These flanges slip the pipe, and their inner diameter is slightly larger than the outer diameter of the pipe. These reinforcements are connected with the pipe through the corner joints at the top and bottom of the flange.

Socket welding flange: a welding flange with an inner bushing installed with a pipe.

The pipe with welded flange is like a sliding flange, only it has the size of a hole and a dark hole. The countersink is slightly larger than the outer diameter of the corresponding pipe, allowing the pipe to be inserted into the flange similar to the sliding flange. The diameter of the smaller hole is the same as the ID number. There is a limit at the bottom of the hole, which is used for pipe support when welding flanges with inner diameter.

The inner diameter of the pipe must be the same. Bushing flange is only applicable to PIBA with specified diameter

150 or less

·Lap flange: lap flange, which is used to install pipe connecting pipe or lining

The total start-up cost of these two projects is about one third higher than that of similar butt welded flanges. There are two assemblies on the flange. Short and movable gasket. The short butt weld is welded to the pipe, and the gasket flange moves freely on the pipe. The material on the flange may be different from the short column material, usually carbon steel, to save cost. The lap flange is almost the same as the sliding flange, but there is an arc at the joint of the hole and the flange. The flange is actually the same as the flange, but it has a radius at the junction of the hole and the flange. This radius is necessary for the normal arrangement of the flange on the stub.

: threaded flange is also called threaded flange, and there are threads in the flange hole. China Professional Flange supplier Manufacture Wilson Pipeline

For pipelines, the matching of threaded flanges in pipelines is widely needed, i.e. E. Other matters Suitable for various industrial applications. These compounds are fast and simple to connect, but can be used under high pressure and high temperature. Threaded flanges are most commonly used in utilities such as air and water. Threaded flange is similar to sliding flange, but the main advantage of threaded hole is that it can be assembled without welding, which explains the application of low pressure in normal atmospheric temperature and in areas with high explosive during welding. Above 25 ° C and below 40 ° C

Page: 1 Blind flange: the blind flange is a circular plate with all connected bolt holes, but there is no central hole, so

This flange is used to close the end of the piping system and the opening of the pressure vessel. When the pipe or container is sealed and must be reopened, it can also easily enter its interior. Blind flanges are used to close the ends of piping systems. It is a circular panel with no central support, but all appropriate bolt holes. Blind flanges are available in various sizes and materials for direct closure at the end of valves or equipment nozzles. This is

Flange flange is easy to enter the pipeline after sealing,China Professional Flange supplier Manufacture Wilson Pipeline

Blind flanges are usually used in petrochemical industry Pipe flanges for public works and water pipes are usually used in high pressure applications

In addition to the most commonly used standard flanges, there are special steel flanges, such as

·Diaphragm flange: when using diaphragm or flow nozzle, use diaphragm flange instead of standard pipe flange. other

Words. Diaphragm flange is used together with diaphragm flowmeter. Its main purpose is to measure the flow rate of gas or liquid in relevant pipelines.

Page: 1 Long neck flange: long neck flange (lwn flange) is also called general flange. This means that the welding flange usually has a long neck, a welding flange with a tapered neck and an inclined end to be welded in the butt joint, but the long welding flange has a short pipe, just like the long neck.Wilson Pipeline Pipe Industry

Welded flanges and Nippo flanges are combinations of welded flanges and allegedly welded brackets or nipolets. These flanges are mainly connected by branches In addition, they have more special flange fittings and branches

·Expansion and transition flanges and transition flanges to increase or decrease pipe holes

Expander and transition pipe flanges are good substitutes for welding adapters. When it is necessary to slightly increase the pipe hole (one or two sizes), it is recommended to use them for large changes in pipe size

Selection of pipe flange connection type

The steel pipe can connect the pipe with the flange (the welding connection is carried out by the weld sleeve) to the flange

Welding, sliding and overlapping flanges) or screwing flanges into pipes (connecting threads with flanges).

Welded joints are used for high pressure, high temperature and diameter pipes and pipes

Two inches high. Threaded connection is used for small-diameter pipes, and is not affected by mechanical expansion force, vibration, contraction, vibration, etc. D. (this may cause the threaded connection to break).

Welding flange

Conical hub welding flange, welding butt end, can be welded on the butt pipe of the same quality

Welded joints shall be subjected to dye (DP) or X-ray and / or ultrasonic (UT) inspection

·The welded connection between neck flange and pipe has good fatigue and mechanical stress

Bell mouth welding

Flange welded flanges are best suited for high pressure piping that is usually less than 2 inches (DN 50)

Fillet weld the pipe to the welded flange hub. In this case, welding quality is very important

Flange connection and proper inspection shall be carried out before the system is put into use

Sliding flange

·Due to low cost and high installation speed (and simplicity), sliding flanges are usually preferred over welded neck flanges. Due to low strength, sliding flanges are usually used in non critical low pressure services

The pipe is welded to the hub and flange hole

NPS 2/(DN65)

Lap joint

This connection is sometimes used for pipes containing expensive materials, such as stainless steel and nickel alloy, because they help

Reduce the total cost of flange connection

·The splicing shall be carried out by welding the short end of the pipe and connecting flange or lap flange.

Manufacturing process of steel flange,China Professional Flange supplier Manufacture Wilson Pipeline

Flanges can be manufactured by forging, casting, cutting or rolling. We mainly produce flanges through forging, cutting and rolling technology

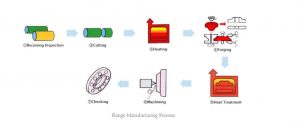

Forging flange process

The forging process usually includes the following processes: selection of high-quality workpiece, heating, forming and cooling

The main raw materials for manufacturing flanges are steel billets or hot-rolled arau mareriak bars

This is the first step that must be taken to ensure good quality during flange production. Raw materials have been repeatedly tested internally to ensure chemical properties

Metallographic analysis

2. Cutting raw materials correctly and strictly controlling the cutting size and proportion can realize comprehensive cost control

3. Heating is an important step in flange quality. The heating temperature must be recorded in detail to avoid overheating that may damage the mechanical properties of metal structures and raw materials.

4. The forging process is divided into free forging and flange stamping forging time and strength

Different pressure levels

5. The purpose of heat treatment is to remove the internal stress of the flange and make the density more uniform

The key is to record the heat treatment temperature and cooling time

6. After the heat treatment is completed, check the forging stock, take batch samples and repeatedly check its chemical composition and mechanical properties to ensure that all components meet the requirements.

7. Process forgings during processing.

Every detail of the flange must be certified CNC and / or machine tool processing

Conduct 100% inspection before delivery of finished products to ensure that the products comply with ASME en or customer standards

Document – record the whole production process and all levels of quality control according to standards

The working procedure conforming to ISO standard is quality assurance

Test certificates: since we are ISO and ped flangemanufacturers, we can issue test certificates to all manufacturers in accordance with en 1030431

Delivery and inspection of goods

Packing: all forgings and flanges are installed in wooden cases, drawers or pallets to ensure the safe movement of goods

Manufacturing technology of plane cutting flange

1. The process here is relatively simple, and the key material is hot-rolled plate.

Production of low thickness flanges and blind flanges. All purchased leaflets are accompanied by the test certificate specified in en 10304 3.12.

3. Heat treatment is not involved in flange manufacturing

Drill the circumference to achieve the required size

(Wilson Pipeline Pipe Industry is a leading manufacturer and supplier of nickel alloy and stainless steel products, including Super Duplex Stainless Steel Flanges, Stainless Steel Flanges, Stainless Steel Pipe Fittings, Stainless Steel Pipe. Wilson Pipeline products are widely used in Shipbuilding, Nuclear power, Marine engineering, Petroleum, Chemical, Mining, Sewage treatment, Natural gas and Pressure vessels and other industries.)

If you want to have more information about the article or you want to share your opinion with us, contact us at sales@wilsonpipeline.com

Wilson Countersink Flanges

Wilsonpipeline.com is a one-stop online destination for all your piping needs, offering a wide range of premium products and services. The website prides itself on its expertise in the field, particularly regarding Wilson Countersink Flanges. These flanges are designed precisely and manufactured to exceed industry standards, ensuring optimal performance and reliability. With their innovative design and exceptional durability, Wilson Countersink Flanges provide seamless integration into various systems, guaranteeing leak-free connections that can withstand even the most demanding environments.

At wilsonpipeline.com, customers are presented with an extensive selection of flange options and benefit from valuable resources such as detailed product descriptions and technical specifications that facilitate informed decision-making. In addition to outstanding product offerings, the website offers exceptional customer support services by knowledgeable professionals who promptly cater to clients’ unique requirements. Whether you are searching for standard sizes or custom-made solutions, rest assured that Wilsonpipeline.com will deliver unparalleled results through their top-of-the-line Wilson Countersink Flanges that meet your exact specifications every time.

Wilsonpipeline.com is a premier online platform that caters to the needs of professionals and industries searching for top-of-the-line Wilson Countersink Flanges. With an unwavering commitment to delivering exceptional products, this website is a trustworthy resource for those seeking high-quality flange solutions that are unparalleled in precision and reliability. Whether you require these specialized flanges for industrial piping systems or structural applications, wilsonpipeline.com offers an extensive range of countersink flanges meticulously crafted to meet the highest industry standards.

Representing excellence in design and engineering, Wilson Countersink Flanges available through this platform exhibit flawless craftsmanship, ensuring optimal performance even under demanding conditions. Our user-friendly interface simplifies ordering while providing detailed product descriptions and specifications, allowing customers to make informed decisions before purchasing.

Backed by years of expertise and a dedication to customer satisfaction, Wilsonpipeline.com sets itself apart as a go-to destination for any professional or industry requiring reliable Wilson Countersink Flanges with exceptional durability and functionality – supporting large and small projects with utmost professionalism every step of the way.